SE-TX SNCR Denitration System

I. Product Summary

SE-TX SNCR Denitration System uses ammonium hydroxide as deductant for denitration. The design scope starts from the connector on the ammonium tank car to the spray gun on the top. The System includes four parts: the ground workshop, ammonium hydroxide and its storage, pressurization and metrological control of ammonium and ammonium spraying equipment. The auxiliary equipment includes ammonia absorption sink and spray on the top of the tank. Main equipment is connected by pipes, the construction of which strictly follows the chemical engineering quality standard, making sure that leakage, dribbling or corrosion will not happen as the System runs for a long time. The conciseness of overall process and reasonable equipment configuration ensure that the system can fully function and fulfill the target, meanwhile lowering the total cost and installation and operation difficulty.

System modules list:

System modules list:

| # | Name |

| 1 | Ammonia Unloading Pump Station |

| 2 | Ammonia Storage |

| 3 | Pressurization Pump Station |

| 4 | Ammonia Absorption Sink |

| 5 | Spraying Pipe System |

| 6 | In-Workshop Pipe System |

| 7 | In-Factory Pipe System |

| 8 | Smart Spray Gun |

| 9 | Air Compression Module |

| 10 | Electric Control, DCS System |

| 11 | Dilution And Recycling Pump Station |

II. Technical Parameter

The amount of spray guns for cement production line is as follow:

| # | Daily Output Of Clinker(T) | Amount Of Spray Guns | Maximum Usage Of Ammonia (Kg/H) | Maximum Power Of Spray Gun(Mpa) | Minimum Pressure For Air Compression(Mpa) |

| 1 | 5000 | 8 | 1600 | 2 | 0.2(cooling) |

| 2 | 2500 | 4 | 800 | 2 | 0.2(cooling) |

| 3 | 1500 | 3 | 600 | 2 | 0.2(cooling) |

III. Features

1. The equipment only takes small space, along with easy installation and maintenance.

2. No catalyst is used, which prevents blockage of pipe or loss of pressure.

3. Low investment and operation cost. The whole reduction process will take place in the discomposing furnace or smoke box, without extra reactor.

4. The system is highly adaptive to various coals.

5. The system is modularized and integrated, with each module independent to each other, which shortens construction time and lowers construction difficulty.

6. The system can be widely applied to construction of new cement production line and reconstruction of old ones.

7. The system can be extended to SNCR/SCR hybrid, which is a practical solution in case of stricter emission standard.

8. The system is equipped with new SE-TX-PQ smart spray gun. Specifically designed for denitration system, the spray gun functions well in atomization and produces even, tiny liquid particles, boosting the mixing of reductant and denitration efficiency. The spray gun can be modified to adapt to various working conditions.

2. No catalyst is used, which prevents blockage of pipe or loss of pressure.

3. Low investment and operation cost. The whole reduction process will take place in the discomposing furnace or smoke box, without extra reactor.

4. The system is highly adaptive to various coals.

5. The system is modularized and integrated, with each module independent to each other, which shortens construction time and lowers construction difficulty.

6. The system can be widely applied to construction of new cement production line and reconstruction of old ones.

7. The system can be extended to SNCR/SCR hybrid, which is a practical solution in case of stricter emission standard.

8. The system is equipped with new SE-TX-PQ smart spray gun. Specifically designed for denitration system, the spray gun functions well in atomization and produces even, tiny liquid particles, boosting the mixing of reductant and denitration efficiency. The spray gun can be modified to adapt to various working conditions.

IV. Main equipment

Ammonia storage module

SE-TX-XABZ ammonia unloading pump station

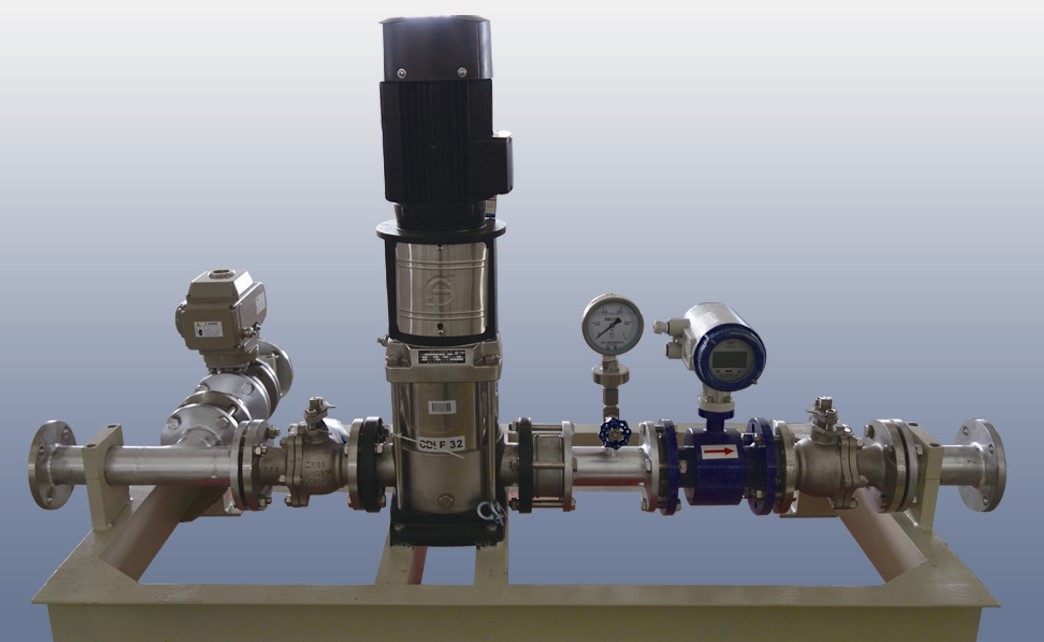

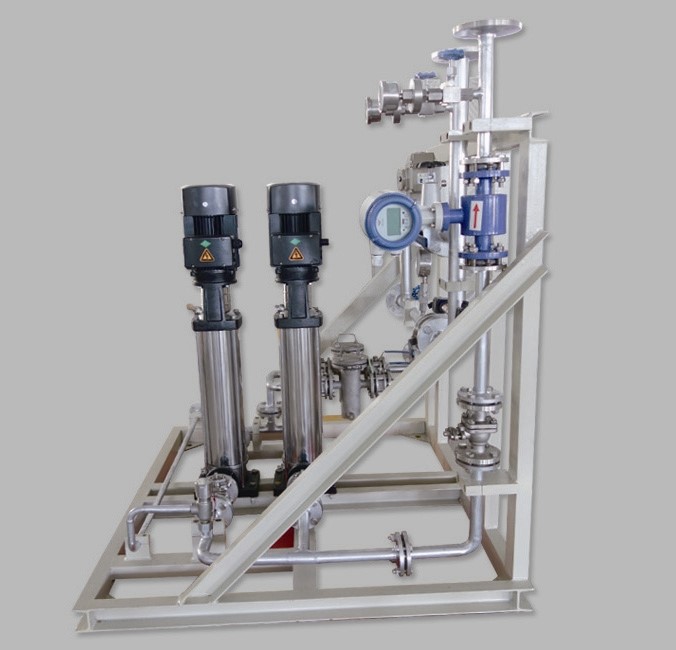

SE-TX-XABZ pressurization pump station

Inside of sorting cabinet

SE-TX-XAC ammonia absorption sink

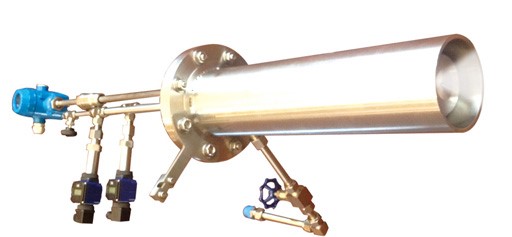

SE-TX-PQ smart spray gun

SE-TX-5000 deinitration system control cabinet

V. Demonstration of Ammonia Atomization

Scan QR Code to Follow Seagle's WeChat Page

Jiangsu (Nanjing) Strong Eagle Automation Engineering Co., Ltd.

Add.:Room 2101, Building 01, Zhongtai International Plaza, 313 Jiangdongzhong Road,

Nanjing, Jiangsu Province, China

P.C.: 210019

Tel.: +86 (025) 52339281 87783181

87783182 87783183

Fax:+86 (025)87783184

Web.:www.njseagle.com

Email:seagle@vip.163.com